Enhancing Industrial Efficiency: Slip Ring Manufacturing and Motor Carbon Brush Supply in India

Introduction:

In the realm of modern industry, seamless energy transmission and efficient machinery operation are paramount. Slip rings and motor carbon brushes are integral components that facilitate smooth power transmission and optimized motor performance. In India, a burgeoning hub of industrial innovation, there exists a network of dedicated manufacturers and suppliers driving advancements in these crucial components.

The Role of Slip Rings:

Slip rings, also known as rotary electrical joints, play a pivotal role in transmitting power, signals, and data between stationary and rotating components in various machines. These ingenious devices find applications across a wide spectrum of industries, including automation, robotics, wind turbines, medical equipment, and more. They enable uninterrupted rotation while ensuring reliable transmission of power and data, thus enhancing the overall efficiency and productivity of complex systems.

The Motor Carbon Brush Connection:

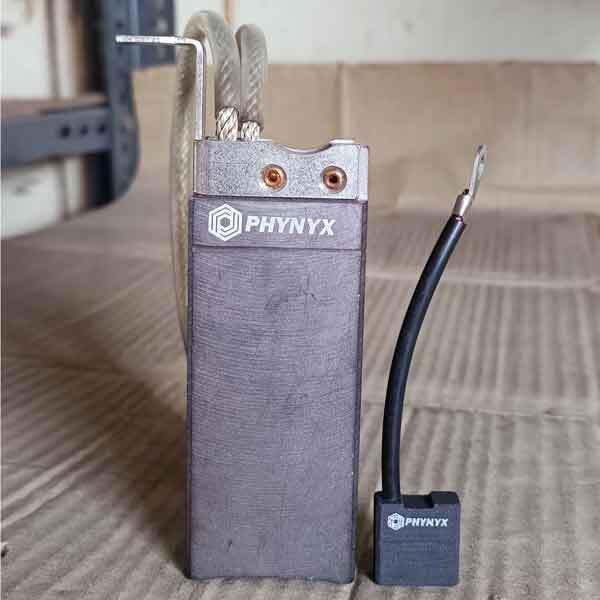

Motor carbon brushes are another indispensable element in the machinery ecosystem. These small yet essential components ensure proper electrical contact between moving parts and stationary conductors in electric motors and generators. By conducting current between the power source and the rotating component, carbon brushes facilitate smooth and consistent motor operation. Quality brushes can significantly extend the lifespan of motors and enhance their performance, making them a critical consideration for industries relying on precision and reliability.

Enterprising Manufacturers and Suppliers:

In India, a thriving network of slip ring manufacturer and motor carbon brush suppliers has emerged to meet the growing demands of various industries. These manufacturers have honed their expertise to design and produce slip rings capable of transmitting power, signals, and data under diverse conditions. With a focus on durability, minimal maintenance, and seamless integration, Indian slip ring manufacturers have gained recognition both domestically and on the global stage.

Similarly, motor carbon brush supplier India have embraced advanced materials and manufacturing techniques to produce brushes that offer high conductivity, low friction, and minimal wear and tear. They cater to a wide range of motor types and specifications, ensuring that industries have access to brushes that optimize motor performance and extend operational lifetimes.

Advancing Industrial Efficiency:

The collaborative efforts of slip ring manufacturers and motor carbon brush suppliers in India have led to a significant boost in industrial efficiency. By providing reliable components that reduce downtime, maintenance costs, and energy losses, these entities contribute to the overall competitiveness of Indian industries on the global platform. Moreover, their commitment to research and development ensures that these components continue to evolve in tandem with technological advancements.

Conclusion:

In the dynamic landscape of industrial innovation, slip rings and motor carbon brushes stand as testament to the meticulous craftsmanship and engineering prowess of Indian manufacturers and suppliers. As industries worldwide seek enhanced efficiency and reliability, the contributions of these components remain invaluable. With their unwavering dedication to quality and innovation, slip ring manufacturers and motor carbon brush suppliers in India are poised to shape the future of industrial progress.

Comments

Post a Comment