Understanding Traction Motor Carbon Brush: Importance and Functionality

Introduction:

The traction motor carbon brush is an essential component of electric locomotives and trains. It plays a crucial role in ensuring the smooth and efficient functioning of the traction motor. Despite its importance, many people are unfamiliar with the traction motor carbon brush and its function. In this article, we will explore the importance and functionality of the traction motor carbon brush.

Importance of Traction Motor Carbon Brush:

The Traction Motor Carbon Brush is responsible for transmitting electrical current from the locomotive's electrical system to the traction motor's rotor. It ensures that the electrical current is transferred smoothly and efficiently, enabling the motor to generate the necessary torque and power required to move the train. The carbon brush also helps to regulate the amount of current flowing to the motor, ensuring that the motor operates at optimal efficiency.

Functionality of Traction Motor Carbon Brush:

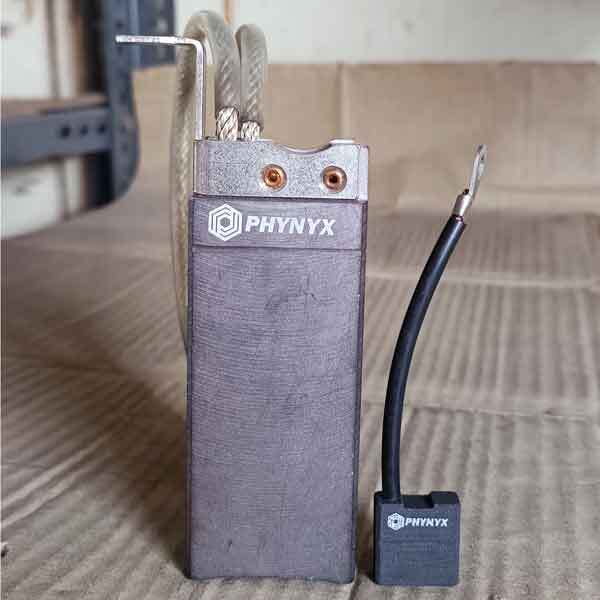

The traction motor carbon brush comprises a block of carbon material held in place by a spring-loaded clamp. The carbon block makes contact with the motor's commutator, which is a series of copper segments mounted on the rotor shaft. As the rotor spins, the carbon block makes contact with the segments, creating an electrical circuit that powers the motor.

The carbon block material used in the traction motor carbon brush is carefully selected to withstand the high electrical currents and temperatures generated by the motor. The carbon block is designed to wear down slowly over time, ensuring a consistent level of contact with the commutator. When the carbon block wears down, it needs to be replaced to maintain the motor's efficiency.

The traction motor carbon brush is an essential component of an electric locomotive's traction motor. It is responsible for conducting electrical current from the locomotive's electrical system to the traction motor's rotor. The carbon brush makes contact with the motor's commutator, which is a series of copper segments mounted on the rotor shaft. As the rotor spins, the carbon block makes contact with the segments, creating an electrical circuit that powers the motor.

The carbon block used in the traction motor carbon brush is typically made of graphite, a highly conductive and durable material that can withstand the high electrical currents and temperatures generated by the motor. The carbon block is designed to wear down slowly over time, ensuring a consistent level of contact with the commutator. When the carbon block wears down to a certain point, it needs to be replaced to maintain the motor's efficiency.

The traction motor carbon brush is a critical component of electric locomotives and trains, and proper maintenance is essential to ensure reliable and efficient operation. Regular inspection and replacement of the carbon brush are necessary to avoid motor failure, which can result in delays, increased maintenance costs, and safety risks.

In conclusion, the traction motor carbon brush plays a crucial role in the functioning of electric locomotives and trains. It conducts electrical current from the locomotive's electrical system to the traction motor's rotor and ensures that the motor operates at optimal efficiency. The proper selection, maintenance, and replacement of the carbon brush are critical to maintaining the motor's efficiency and ensuring reliable train operations.

Click here for more information:-

Comments

Post a Comment