The Importance of Choosing a Reliable Carbon Brush Manufacturer

Carbon brushes are an essential component of many electrical machines, including motors, generators, and power tools. As a result, the demand for carbon brushes is constantly growing. In this article, we will discuss the importance of choosing a reliable Carbon Brush Holders Manufacturer, the process of making carbon brushes, and the benefits of using high-quality carbon brushes.

Importance of Choosing a Reliable Carbon Brush Manufacturer

Choosing a reliable Carbon Brush Supplier is crucial, as the quality of the carbon brushes will directly affect the performance and lifespan of the machines they are used in. A reliable manufacturer will have the expertise and technology to create carbon brushes that are durable, efficient, and reliable. In addition, a reputable manufacturer will also provide excellent customer service and support, including technical assistance and fast delivery.

Process of Making Carbon Brushes

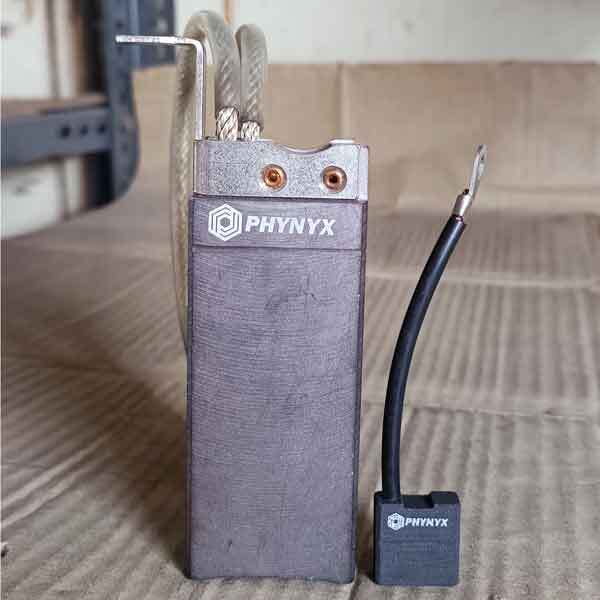

The process of making carbon brushes begins with selecting the right materials. Carbon brushes are typically made from a mixture of graphite and other conductive materials, such as copper or silver. The materials are then compressed and molded into the desired shape. After molding, the carbon brushes are baked at high temperatures to improve their electrical conductivity and mechanical strength. The carbon brushes are then trimmed to the correct size and shape, and any excess carbon is removed.

Finally, the carbon brushes are fitted with metal connectors, which allow them to be connected to the machine. The finished carbon brushes are then inspected for quality and tested to ensure they meet the required specifications.

Benefits of Using High-Quality Carbon Brushes

Using high-quality carbon brushes can provide a range of benefits, including:

Improved Performance: High-quality carbon brushes are designed to provide consistent and reliable performance, ensuring that machines operate smoothly and efficiently.

Longer Lifespan: Carbon brushes that are well-made and durable will last longer, reducing the need for frequent replacements and increasing the lifespan of the machine.

Reduced Maintenance: By using high-quality carbon brushes, machines require less maintenance and repair, saving time and money.

Enhanced Safety: Poor quality carbon brushes can cause machines to malfunction or even pose a safety hazard. High-quality carbon brushes ensure that machines operate safely and reliably.

Conclusion

Choosing a reliable Carbon Brush Manufacturer is essential for ensuring the performance and lifespan of electrical machines. The process of making carbon brushes is complex and requires expertise and technology. By using high-quality carbon brushes, machine operators can improve performance, reduce maintenance and repair, and enhance safety. With the growing demand for carbon brushes, it is important to choose a manufacturer that is experienced, reliable, and able to deliver high-quality products and customer service.

Click Here For More Information:-

Comments

Post a Comment