How to Keep a Motor's Carbon Brush in Top Shape

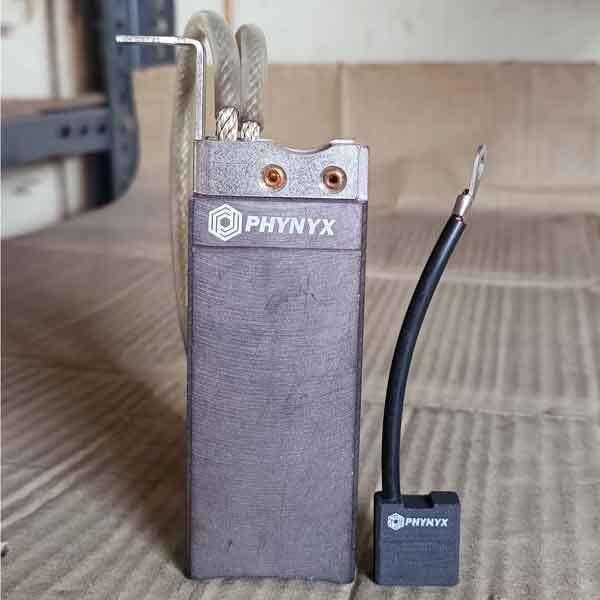

Each and every engine has a carbon brush within it, and this brush assumes a significant part in the activity of the machine. Indeed, even normal apparatuses like dishwashers and your kitchen stand blender have these brushes within them. The brush is the part that really conveys signs or energy to a moving part inside the engine. It makes the necessary association between the part that isn't moving and the part that is moving. By and large, these brushes are made of carbon and molded like a 3D square.

The majority of them work with a spring, which squeezes it up onto the shaft. They likewise will generally have a wire on the highest point of them, which administrations to rub the moving part and communicate the energy or transmission. These brushes break down quit effectively, so taking great consideration of them is significant. The following are five consideration ways to manage a carbon brush inside any apparatus or machine:

1. Utilize a similar kind of brush inside a similar machine-more often than not. Most engines have more than one brush within them, and as a rule you will need to involve similar brush in all pieces of it. In extremely uncommon cases, particularly when you are managing medium or huge engines, you might track down the need to utilize at least two unique brushes inside the engine. Make certain to look at with a specialist to find on the off chance that you end up having one of these extremely intriguing cases.

2. Ensure the strain is kept even across the brushes. One of the fundamental reasons carbon brushes break down is on the grounds that the strain inside the engine is being applied on them unevenly. Every maker discharges specialized execution tables for every one of their brushes. These tables are a fundamental piece of establishment and support of the brush. On the off chance that an excess of tension is applied on one brush, starts and overheating could result. The objective is for even wear across each of the brushes inside the engine.

3. Strain ought to continuously be applied utilizing the specs from the appropriate specialized exhibition table. Regardless of whether you have even tension being applied across each of the brushes inside the machine, you will in any case see them break down far and away excessively fast assuming that the strain inside the engine is set excessively high. Then again, on the off chance that the strain on the brushes is excessively low, sparkles and in general precariousness of the engine could result. The specialized tables for the brushes you are utilizing are continuously going to be your dearest companion with regards to establishment and upkeep for them.

4. Supplant every one of the brushes inside an engine simultaneously. Since you're holding back nothing across the brushes, it is all fundamental that you supplant them all simultaneously. Blending old and new parts is never astute in light of the fact that it by and large makes the power be circulated unevenly all through the engine.

5. Different choices for supplant the brushes. Assuming that supplanting the brushes simultaneously isn't all a choice since it will influence creation too incredibly, there are different choices. The best guidance for enormous engines utilized in modern settings is to supplant 20% of each bar of brushes immediately. Do this about each one to about fourteen days to downplay the free time of your machines.

The brushes are a fundamental piece of the general situation of your business, so it is important that you keep them all ready consistently.

For More Information :-

Comments

Post a Comment