Carbon Brushes in Electric Motors: An Overview and Maintenance

Carbon brushes, or electric engine brushes, assume a significant part in engines and generators, filling in as electrical conduits. This is accomplished by passing electrical flow between the engine's fixed and pivoting wires. A carbon brush might have at least one carbon block and at least one shunt or terminal. There are in many cases various carbon brushes in an engine or generator.

Various Grades of Carbon Brushes

Albeit the principal brushes were made of copper, carbon ultimately turned into the favored engine brush material in light of its high contact opposition, low grinding, and capacity to oppose arcing.

Carbon brushes are isolated into four brush-grade families:

- Carbon graphites

- Electrographites

- Graphites

- Metal graphites

- Carbon-Graphite Brush

One of the primary carbon brushes, this is appropriate for use on more established, more slow machines with the most extreme surface paces of 4,000 feet each moment. This kind of carbon brush is utilized in metal contacts and bases and is seldom found in commutators given the great erosion it produces.

Electrographite Carbon Brush

Electrographite brushes are handled at high temperatures, making them longer-enduring and ideal for use in commutators. These brushes can be treated with natural or inorganic materials to make them more solid. This kind of brush is great for use in various working conditions, remembering those for which high temperatures and low stickiness are the standards.

Graphite Carbon Brush

Described by layers of material, graphite brushes are made by restricting either normal or fake graphite with gum or pitch. These brushes are much of the time utilized in commutators and slip rings. Their high densities and low permeable characteristics make them ideal for defiled conditions.

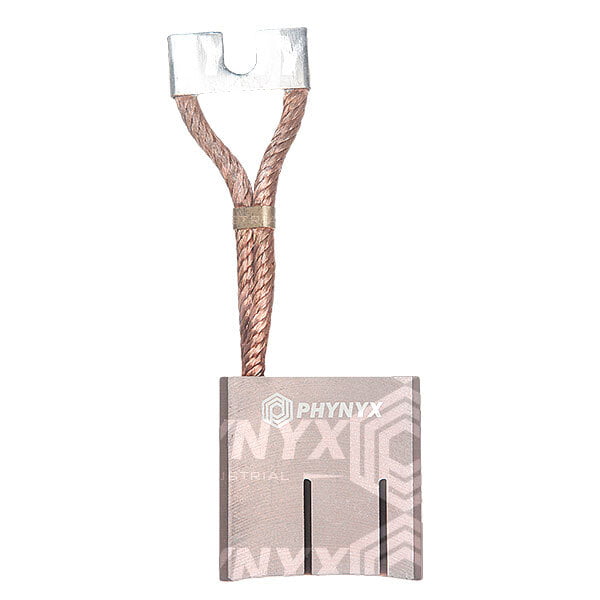

Metal Graphite Carbon Brush

Metal graphite brushes are made by consolidating graphite with fine metal powders like copper, silver, tin, and lead. Because of their low resistivity, these brushes get utilized in a bunch of ways. They should be visible in forklift truck engines, battery chargers, welding generators, slip rings with high brush current densities, plating generators, and DC machines, and are frequently utilized as establishing brushes.

Keeping up with Your Carbon Brushes

Gear breakdowns are frequently credited to carbon brush disappointments. Knowing how to appropriately keep up with — and when to supplant — carbon brushes is critical to staying away from margin time.

While igniting happens, or on the other hand, if there is one more issue with the brush, the accompanying carbon brush upkeep strategies are suggested:

- Affirm there is no conspicuous harm or soil on the brush.

- Guarantee that the brushes can move in their holders.

- Look at the springs of each brush and change the tension in a like manner.

- Investigate the commutator for indications of mica, blades, and additional slugs.

- Ensure there are no darkened, pitted, or consumed fragments in the commutators.

- Search for roundness and bar-to-bar deviations in the commutators.

- Lay out that the risers are appropriately associated.

- Check the brush drop or field-structure bend of a machine running at a typical burden.

- Check whether the brushes vibrate by holding a piece of protecting material on top of the brush.

- Verify that the course is not vibrating unreasonably.

Ordinary cleaning of engines with an air blower will assist with keeping away the advancement of large numbers of these issues. On the off chance that the above methodology has been performed you haven't settled the issue, contact the carbon brush maker or your wholesaler. Administration or substitution of your brushes might be required.

Legitimate Protection Support

Albeit now and again barely noticeable, carbon brushes are one of the most basic parts of engines and generators. Without brushes, engines and generators couldn't direct power — and hence, couldn't work.

Ensure you're not forgetting about engine support. Legitimate engine checks and cleaning ought to altogether expand the existence of your carbon brushes and assist you with staying away from any critical carbon brush support issues.

Click here for more information:-

Comments

Post a Comment